矿渣磨 mill

2019-09-13T15:09:49+00:00

矿渣粉磨工艺介绍 知乎 知乎专栏

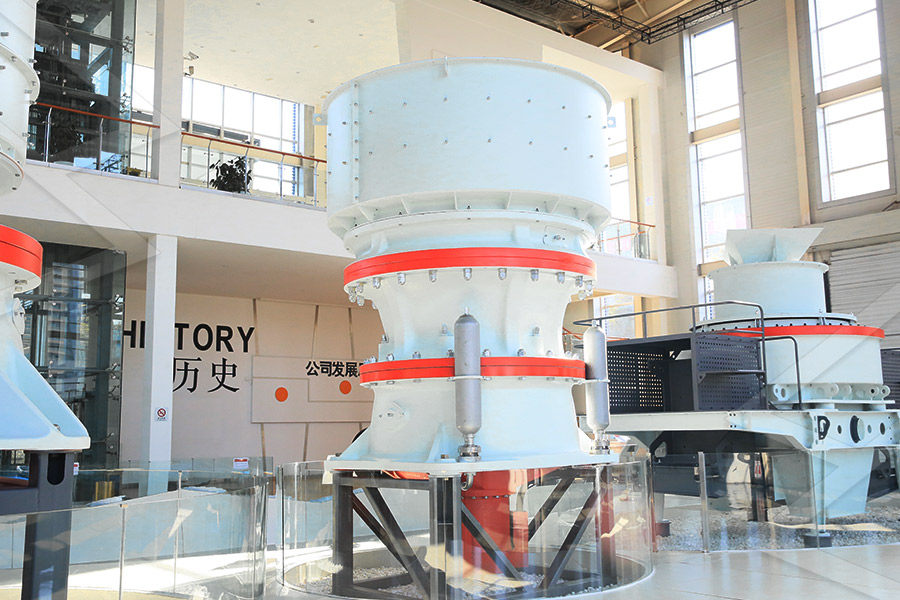

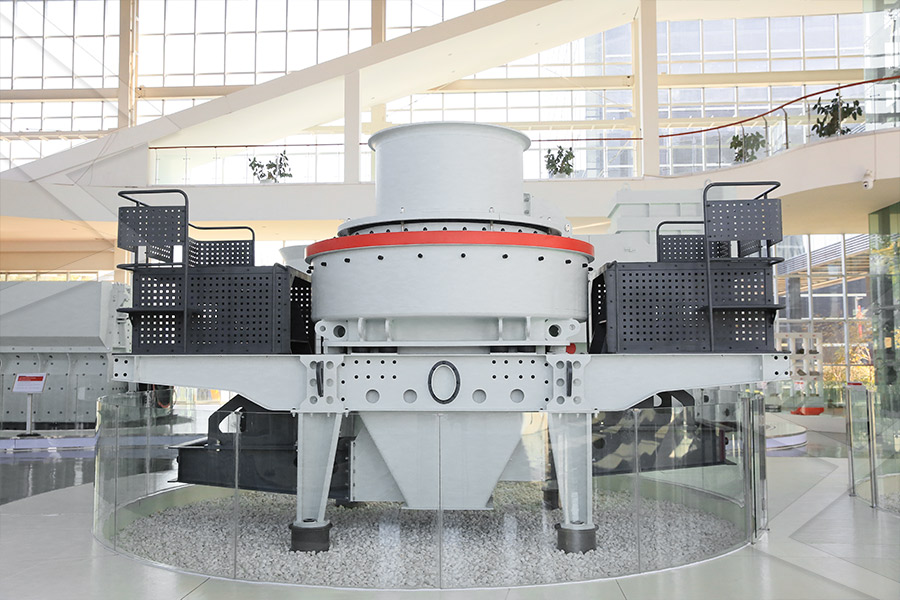

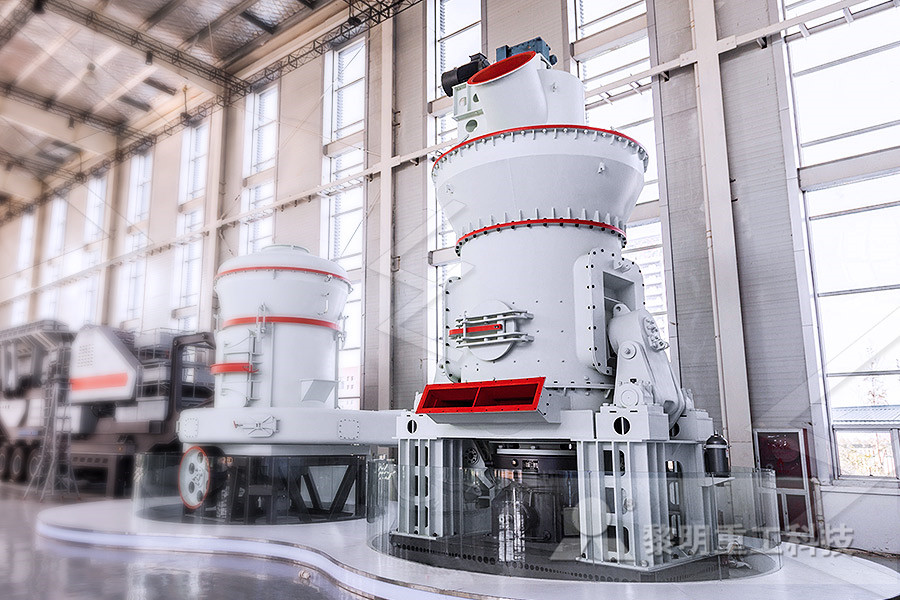

2022年7月19日 矿渣立磨是整个矿粉线的核心,集粉磨、烘干、选粉、输送为一体,是最终矿粉成品质量的关键。 矿渣粉磨所需要的烘干热能由热风炉提供,用矿渣立磨研磨物 2022年1月4日 高炉矿渣通过皮带机,输送入气动双翻板阀,之后进入立磨,矿渣在立磨内部被粉磨成微粉,同时被热风炉会对矿渣送热风进行干燥。 选粉机分选过后的微粉,由 矿渣立磨粉磨典型工艺及常见问题问答黎明重工科技股份有限公 2011年6月20日 年产60万吨矿渣粉生产线烘干粉磨系统设计摘 要:矿渣粉可以改善混凝土的耐久性和工作性,是一种性能优良的矿物细掺料,制造矿渣粉是实现高炉矿渣高效利 年产60万吨矿渣粉生产线烘干粉磨系统设计 豆丁网

钢渣磨粉设备钢渣粉磨生产线 知乎 知乎专栏

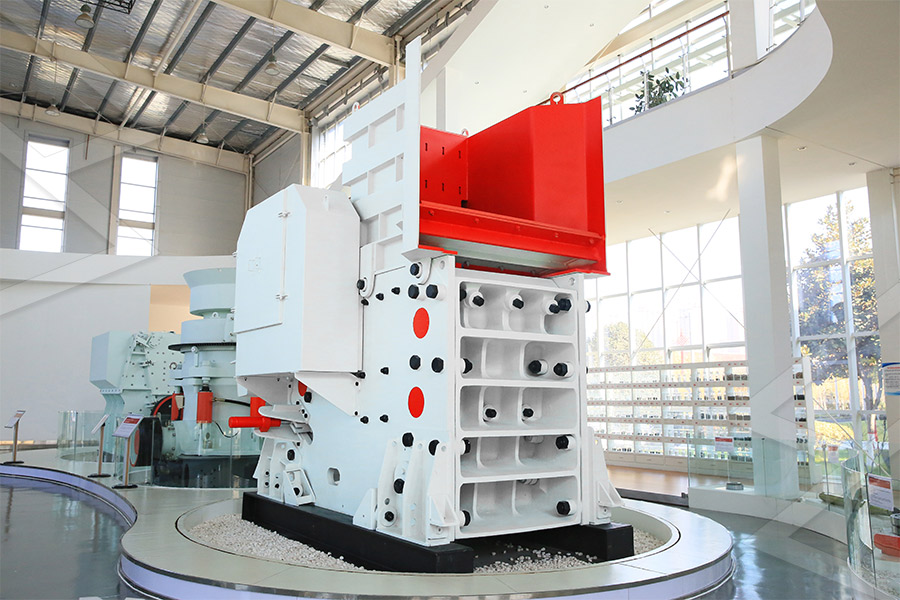

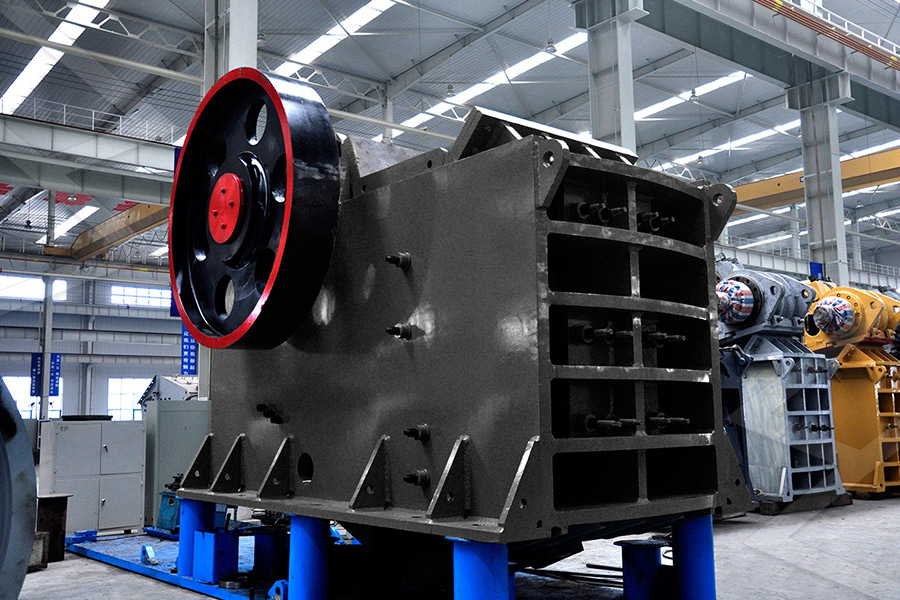

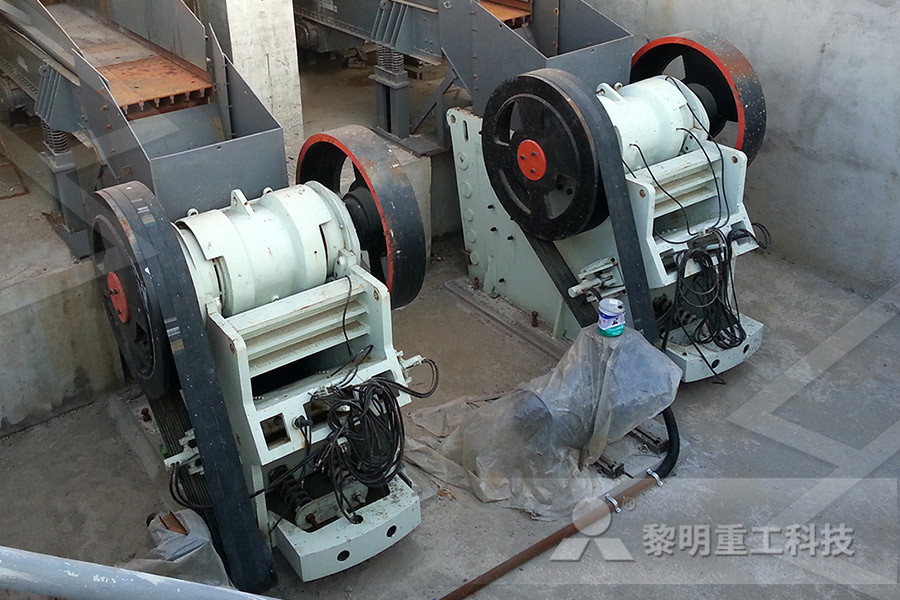

钢渣磨粉设备钢渣粉磨生产线主要用于钢渣处理过程中钢渣的粉磨。我公司生产的钢渣磨粉设备钢渣粉磨生产线产量为10~155 t/h,所产钢渣微粉比表面积为300~700 cm²/kg。具 1、破碎设备 矿渣需破碎之后用于道路基层或垫层,常用的破碎设备有:反击式破碎机、对辊式破碎机、圆锥式破碎机以及矿渣移动破碎站等。 2、磨粉设备 矿渣微粉作为高性能混 走出“一无是处”的尴尬!工业固废再利用系列——矿渣篇 知乎According to Martins (Martins, 2015), the Mine to Mill approach is based on the identification of constraints and possible opportunities to maximize the profitability of the global What is Mine to Mill? Part I (M2M) OPitblast Blog

矿渣的化学成分机矿物组成 知乎 知乎专栏

2019年8月26日 那么矿渣的化学成分都有些呢? 经过分析,成分主要有CaO、SiO2、Al2O3、MgO、MnO、Fe2O3 等氧化物和少量硫化物如CaS、MnS等,一般来说,CaO Were able to accept the fact that regrinding mill and mill or grinding Media affect downstream performance or not The system will contain a lot of circulation loads, and as 选择重新磨坊 研磨和分类电路 冶金和矿物处理工程师 www MilliQ ® IQ 7003/05/10/15超纯水和纯水系统 MilliQ ® 实验室用水解决方案的台式水系统系列包括纯水和超纯水两种系统,可满足任何实验室要求。 从灵敏的质控分析到缓冲液制 MilliQ® 台式实验室纯水系统 MilliporeSigma

Tandem cold mills for steel SMS group GmbH

It's a huge challenge to produce smaller batches profitably, especially when not running the mill at full capacity Our new CVC ® plus M 18/4 stand for reversing and tandem mills is a multipurpose mill that covers a very wide product range from soft IFgrades (Interstitial Free) right through to HSS (High Strength Steel) and stainless steelsFind out how the Fitzpatrick Hammer Mill could be the solution to your particle size reduction needs by requesting our brochure today Screen type and Rotor speed Altering the rotor speed and screen design makes it Fitzpatrick Powder Milling EquipmentBenefit from AG and SAG Mill in many drive arrangements, sizes and bearing designs Your operation requires a Semi Autogenous Mill (SAG mill) or Autogenous Mill (AG Mill) that is flexible, durable, costefficient SAG Mill Autogenous and SemiAutogenous Mills

VXPmill for fine ultra fine grinding

However, the mill has been used to preferentially grind the coarser “hump” in bimodal distributions without over grinding the finer part of the distribution Grinding efficiency is affected by a wide range of variables Process 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s Energy Use of Fine Grinding in Mineral Processing SpringerLinkIt's a huge challenge to produce smaller batches profitably, especially when not running the mill at full capacity Our new CVC ® plus M 18/4 stand for reversing and tandem mills is a multipurpose mill that covers a very wide product range from soft IFgrades (Interstitial Free) right through to HSS (High Strength Steel) and stainless steels We install the CVC ® Reversing cold mills for steel SMS group GmbH

7 Best Milling Machines (Affordable Mills in 2023)

2023年5月25日 Alan Lewis Rankings, Machining Finding the right mill for you isn’t always easy For starters, most milling machines are very expensive and designed for industrial settings, so finding an Milling The grinding of solid samples is essential to ensure precise analysis It is important that the grinding leads to the homogeneity and desired fineness of the sample The type of mill to be used depends on the properties of the substance and the quantity of the sample For example, brittle materials are ground with a beater, fibrous Milling IKA2023年4月28日 Top 10 Best Benchtop Milling Machines 2023 (All Prices) April 28, 2023 Alan Lewis Rankings If you’re a hobbyist working with limited space, the best benchtop milling machines can help you boost your home workshop to the next level With no shortage of options, it can feel a little overwhelming – particularly for beginnersTop 10 Best Benchtop Milling Machines 2023 (All Prices)

GitHub comlihaoyi/mill: Your shiny new Java/Scala

exampleserver, integrationserver, examplefork and integrationfork cover the same test cases as the local tests described above, but they perform packaging of the Mill core modules into an Find out how the Fitzpatrick Hammer Mill could be the solution to your particle size reduction needs by requesting our brochure today Screen type and Rotor speed Altering the rotor speed and screen design makes it Fitzpatrick Powder Milling EquipmentBenefit from AG and SAG Mill in many drive arrangements, sizes and bearing designs Your operation requires a Semi Autogenous Mill (SAG mill) or Autogenous Mill (AG Mill) that is flexible, durable, costefficient SAG Mill Autogenous and SemiAutogenous Mills

VXPmill for fine ultra fine grinding

However, the mill has been used to preferentially grind the coarser “hump” in bimodal distributions without over grinding the finer part of the distribution Grinding efficiency is affected by a wide range of variables Process It's a huge challenge to produce smaller batches profitably, especially when not running the mill at full capacity Our new CVC ® plus M 18/4 stand for reversing and tandem mills is a multipurpose mill that covers a very wide product range from soft IFgrades (Interstitial Free) right through to HSS (High Strength Steel) and stainless steelsTandem cold mills for steel SMS group GmbH2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s Energy Use of Fine Grinding in Mineral Processing SpringerLink

Reversing cold mills for steel SMS group GmbH

It's a huge challenge to produce smaller batches profitably, especially when not running the mill at full capacity Our new CVC ® plus M 18/4 stand for reversing and tandem mills is a multipurpose mill that covers a very wide product range from soft IFgrades (Interstitial Free) right through to HSS (High Strength Steel) and stainless steels We install the CVC ® A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processes Mill (grinding) Wikipedia2016年3月26日 mill:磨、研磨 finish:抛光 mill finish :磨光 磨光是通过磨轮的旋转,利用磨料的刃磨作用,使表面光滑的过程。 磨光的目的在于除去金属工件表面的毛刺、氧化皮、腐蚀痕、划痕、砂眼、锈迹及气孔等,使工件表面平整、光滑。 已赞过 已踩过 你对这个回答的评价是? 评论 收起 郑州基实抛丸机钢 表面处理MILL FINISH 是什么意思 百度知道

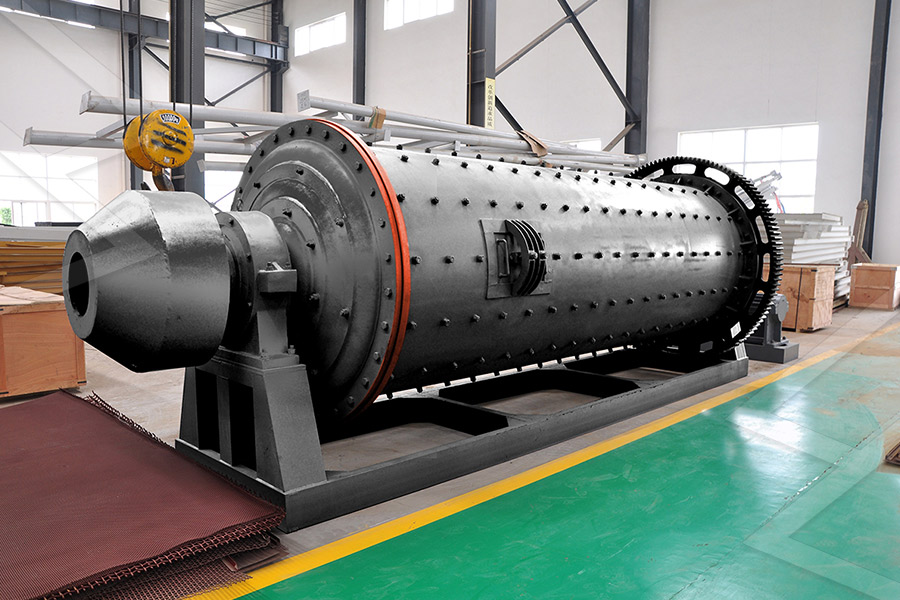

矿渣磨规格

矿渣磨江苏鹏飞集团股份有限公司 首页 > 产品中心 > 粉磨设备 > 矿渣磨 矿渣磨 序号 产品规格 (m) 生产能力 (t/h) 筒体转速 exampleserver, integrationserver, examplefork and integrationfork cover the same test cases as the local tests described above, but they perform packaging of the Mill core modules into an GitHub comlihaoyi/mill: Your shiny new Java/Scala